Considerations and Tips

|

| Rule of Thumb |

Check the competitors' label! Most product information is listed on the product label. |

| Why gauge is not always important |

Film thickness is no longer the only standard for judging overall bag strength. The development of advanced resins and additives has changed the standard method for selecting the correct can liner. Manufacturers are producing thinner, lighter trash bags that are stronger and more durable than thicker bags made from lesser quality raw materials. |

| When choosing a bag remember... |

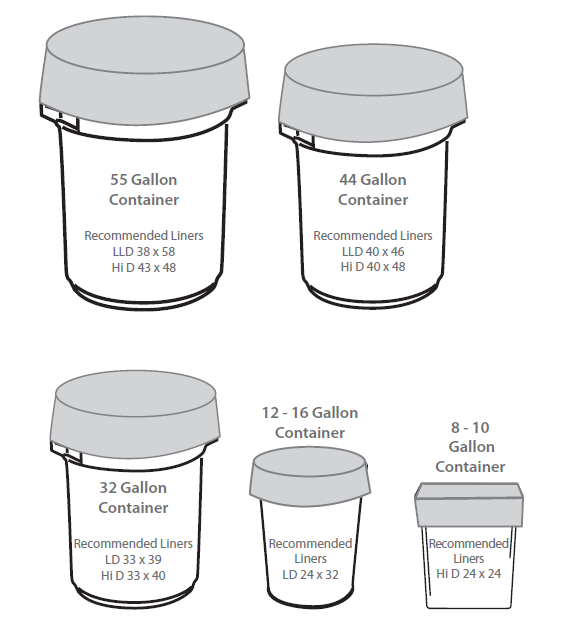

1) Choose bag size and bottom seal of the liner based on type of trash can being used

- Some manufacturers will state liner sizes in “gallons” in an attempt to offer smaller liners that use less plastic.

- Most manufacturers use the item number to indicate the liner size even though it is not the actual size of the liner.

- Star sealed can liners are the most expensive and highest quality since they conform better to larger, round trash cans.

- Gusset sealed bags are the least expensive and will tend to leak, unlike star seal or flat seal.

2) Choose plastic type (HD or LLD)

- High density liners are lower in cost than low density liners.

- Recycled plastic or repro liners yield a bag with a lower capacity for weight at a lower cost. A thicker repro liner is needed to lift the same amount of static weight as a virgin resin bag.

3) Verify the gauge or thickness of the liner

- Some manufacturers avoid stating the actual thickness of the liners, an attempt to sell less plastic for a higher price.

- There is no governing agency to ensure that thicknesses listed on the carton is what is actually in the box. Weighing the case and comparing against other brands will help identify any differences. Less weight equals less plastic.

- Many manufacturers will test liner samples in their lab to give you the actual mill/mic thickness of a competitive product for comparison purposes.

2) Choose plastic type (HD or LLD)

- High density liners are lower in cost than low density liners.

- Recycled plastic or repro liners yield a bag with a lower capacity for weight at a lower cost. A thicker repro liner is needed to lift the same amount of static weight as a virgin resin bag.

3) Verify the gauge or thickness of the liner

- Some manufacturers avoid stating the actual thickness of the liners, an attempt to sell less plastic for a higher price.

- There is no governing agency to ensure that thicknesses listed on the carton is what is actually in the box. Weighing the case and comparing against other brands will help identify any differences. Less weight equals less plastic.

- Many manufacturers will test liner samples in their lab to give you the actual mill/mic thickness of a competitive product for comparison purposes.

4) Check how many liners are in the case and calculate the cost per can liner pricing

- Fewer liners in a case gives the appearance of a better value because of the lower price

- Calculating the cost per can liner will give you the true cost per use.

5) When in doubt, weigh the case! This will help determine what’s really in the box! |

| What is Static Load? |

Static load (lifting strength) is the best way to choose bag strength. Approximate gauge equivalents for static load are…

Weight

|

Linear Low Density

(in Mils)

|

High Density

(in Microns)

|

| Refuse Weight |

0.30 – 0.35 Mil |

6 Mic |

| Light Weight |

0.36 – 0.49 Mil |

7 – 9 Mic |

| Medium Weight |

0.50 – 0.60 Mil |

10 – 12 Mic |

| Heavy Weight |

0.61 – 0.74 Mil |

13 – 14 Mic |

| Extra Heavy Weight |

0.75 – 0.80 Mil |

15 – 17 Mic |

| Super Tuf |

0.81 – 1.0 Mil |

|

| Super Heavy |

1.1 – 1.2 Mil |

|

| XXH |

1.3 – 1.9 Mil |

18 – 24 Mic |

| XXXH |

2.0 – 3.0 Mil |

|

|

| Strength Grade Key |

| Light |

For crumpled papers, cups, light waste, etc. |

|---|

| Medium |

For packaging waste, wet paper, etc. |

|---|

| Heavy |

For light wood, metal scraps, wet cardboard, etc. |

|---|

| Extra Heavy |

For heavy, sharp or wet trash |

|---|

| Super/Extra Heavy |

For heaviest cleanup jobs in warehouese, cafeteria or facility grounds. |

|---|

|

| Film Colors |

- Black, white and natural are the most common

- BNatural (otherwise clear or transparent) are ideal for areas where transparency is required for security purposes

- Specialty colors (red, yellow, blue, brown, gray) are ideal for at-a-glance content identification (i.e. blue bags may indicate recyclable waste)

|

| Size of Trash Liner |

- 2 dimension (i.e. 38x60) used with Star, Flat and occasionally Gusset seal bags

- 38 = face (17) + depth (21) of the bag

- 60 = height of the bag

- 3 dimension (i.e. 17x21x60) used only on Gusset seal bags

- 17 = face of the bag

- 21 = depth of the gusset

- 60 = height of the bag

Tricks of the Trade

- Some manufacturers will state liner sizes in “gallons” instead of dimensions in an attempt to offer smaller sized liners that use less plastic

- Most manufacturers use the item # to indicate the liner size, that’s not always the case!. Don’t be fooled by the item #, check the actual size on the box

|